Laser Diameter Gauges

Laser Diameter Gauge

(0 Review)

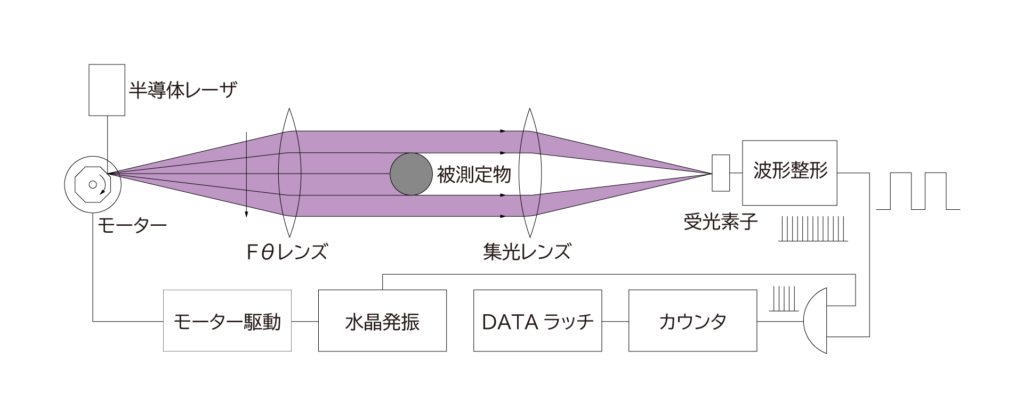

This is a standard single-axis measurement. A laser beam is emitted from the light-emitting side to the light-receiving side, and the time it is blocked by the object being measured is converted into length.fds fs f fds fds ds s sd dsf fd fdd vd d d ds ds fffffffffffffffffffffffffffffffffs fds fds

MKS : J-8521

Category : Laser Diameter Gauges

Tags : diametergauge, beta, takikawa, odcontroller

What is a laser outer diameter measuring instrument?

A laser diameter measuring instrument, also known as a laser microgauge, measures the outer diameter of a part by converting the time it takes for the laser beam to be blocked by the object being measured into a length.

Measurement is performed by scanning the semiconductor laser light in parallel using a polygonal rotating mirror and an Fθ lens. The laser beam that has scanned the object is received by a photodiode via a condenser lens and converted into an electrical signal.

Laser outer diameter measuring instrument LDM series

Laser outer diameter measuring instrument LDM series

Takikawa Engineering's LDM series of laser outer diameter measuring instruments are called by various names, such as laser microgauges, laser micrometers, dimension measuring instruments, and width measuring instruments, depending on the industry and application.

The LDM series uses a combination of detector and display depending on the application.

Non-contact measurement using laser light enables stable measurement of the outer diameter of an object without being affected by external light such as sunlight or fluorescent lights.

The LDM series allows you to select the following types depending on your application, allowing you to configure the optimal system.

- Multi-directional coaxial type that enables high-precision measurement

- Separate type that can flexibly accommodate various measurement environments

- Oscillating type for full circumference measurement

Based on customer feedback, we have also developed a lineup of models that can handle a wide range of measurement targets (workpieces), from ultra-fine wires of 0.02 mm to large diameters of several meters.

Advantages of non-contact measurement

Non-contact measurement offers the following benefits:

- Since there is no need to hold the workpiece with tools such as calipers that can perform accurate measurements

, the external dimensions of workpieces made of soft materials such as rubber and tubes can also be measured accurately. - There is no variation in measurement results

. Compared to measurements using calipers or micrometers, which are easily affected by the skill and experience of the operator, measurement results are more stable. - It does not damage the object being measured

, and does not scratch the surface even when measuring rubber hoses and other automotive parts or medical equipment.

Target work (object to be measured)

Medical tubing (silicone tubing, catheters, IV tubing, etc.)

Rubber and plastic hoses (automotive hoses, fuel hoses, air hoses, etc.)

Electric wires and cables (fiber optic cables, high-voltage cables, communication cables, wire harnesses, etc.)

Metal pipes (stainless steel pipes, copper pipes, aluminum pipes, etc.)

Precision parts (shafts, rollers, etc.)